| 型號: | WJ |

|---|---|

| 品牌: | 肇慶西江 |

| 原產地: | 中國 |

| 類別: | 包裝印刷、紙業 / 包裝用品 |

| 標籤︰ | 單瓦線 , 單麵線 , 生產線 |

| 單價: |

¥1600000

/ 件

|

| 最少訂量: | 1 件 |

| 最後上線︰2025/02/24 |

2016促銷系列彩盒瓦楞紙板生產線價格面議

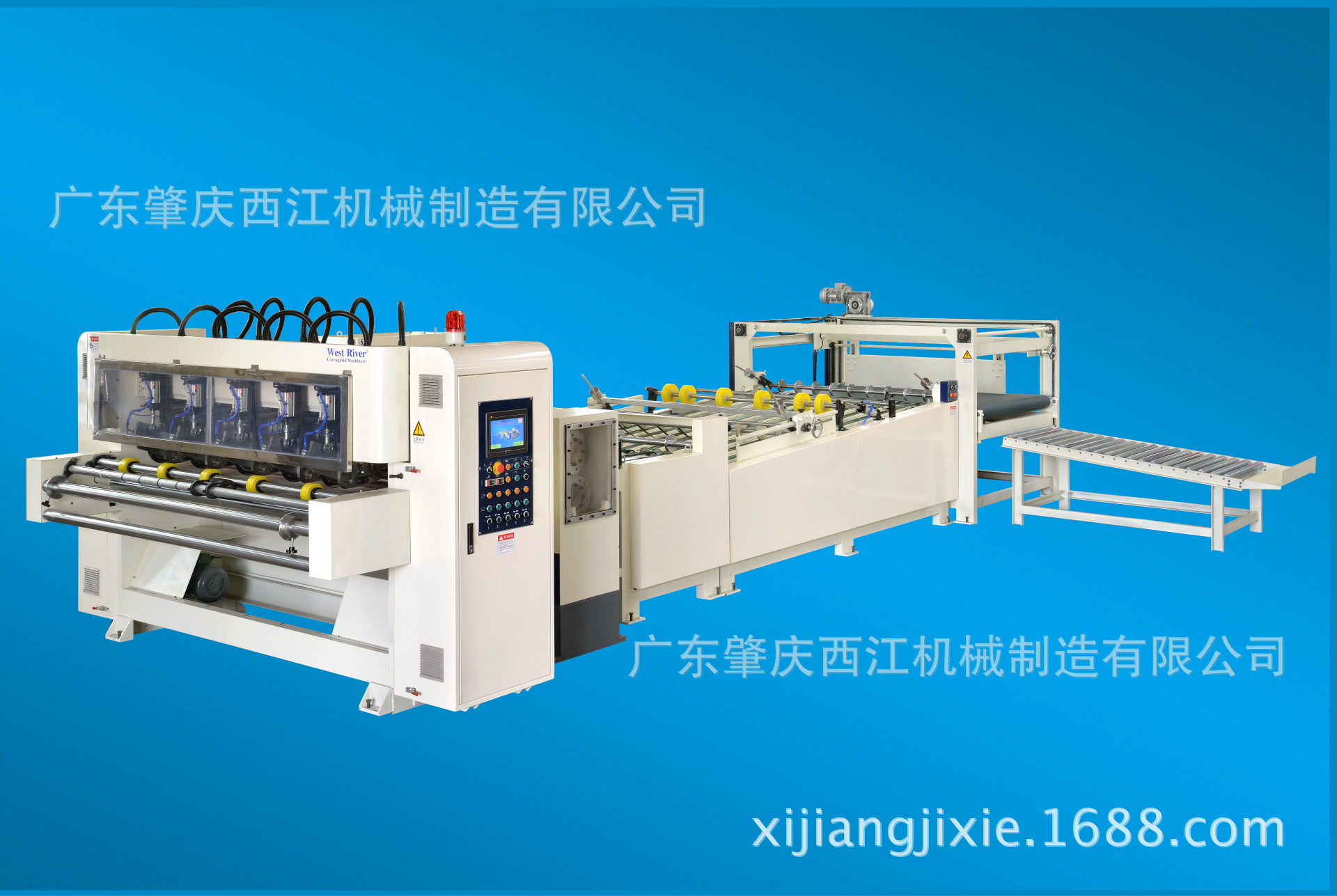

GSQ18-E電腦伺服薄刀單瓦切紙機

GSQ18-E Computer Servo Thin blade Single Face Shearer Cut-Off

1、主要技術指標

(1).有效寬度:1650-2550毫米;

(2).最高機械速度:120米/分

(3).縱切刀數:5刀;(一開四)

(4).最小縱切寬度:240毫米;

(5).排刀時間:﹤4秒;

(6)、排刀精度:±1毫米;

(7)、橫切精度:±1毫米(勻速);

(8)、切長範圍:300~1300毫米

(9)、堆碼高度:800~1000mm

1, Main technical indicators

(1). Effective width: 1650 -2550mm;

(2). Maximum mechanical speed: 120 m / min.

(3). Quantity of slitting blades: 5 blades; (1 to 4 sheets)

(4). Minimum slitting width: 240 mm;

(5). Arrange blades Time: <4 seconds;

(6), Arrange blades precision: ± 1 mm;

(7), Transverse cut accuracy: ± 1 mm (uniform);

(8), Cut length range: 300 to 1300 mm

(9), Stack height: 800 ~ 1000mm

2、功能特點與配置:

2, Features and configuration:

(1).同步進紙輸送

*進紙部分採用上下皮帶夾持式結構,保証入紙順暢,同時保護瓦楞不受損;

*臺灣城邦電機、變頻器控制進紙輸送,輸送速度與單面機速度自動同步

(1). Synchronous In-feed Conveyor

* In-feed Unit, select upper belt and lower belt holding structure, ensure smooth feeding paper, while protecting flute avoid of injure in the meantime;

* Taiwan ChengBang motor, inverter control In-feed conveyor, conveying keep speed automatic synchronization of the single machine.

(2).全自動薄刀縱切

*鎢鋼薄刀縱切,自動磨刀,自動冷卻,刀片壽命長,紙板分切質量高

*縱切刀排單電機獨立伺服控制(一刀一台伺服電機控制),排單快速、精確、可靠

*進紙電機、變頻器控制,可獨立調速也可跟隨紙板速度同步

*縱切刀由獨立的電機驅動,由變頻器調整轉速。

*移動導軌為線性滑軌

*薄刀昇降氣動控制

(2). Automatic thin blade slitting

* Tungsten steel thin blade slitting, automatic sharpening, automatic cooling and blade long using life, cardboard high quality cut.

* Slit blade arrange order motor independent servo control (1 blade controlled by 1 servo motor), arrange order fast, accurate and reliable

* In-Feed motor controlled by inverter, can independent follow speed adjustment accord cardboard speed synchronization.

* Slit blade is driven by independent motor, the speed is adjusted by the inverter.

* Mobile guide rail is linear slide rail

* Thin blade pneumatic control lifting

(3).氣動系統

*臺灣亞德客電磁閥、氣動閥、調壓閥、三聯件等氣動元件

(3). Pneumatic system

* AirTAC solenoid valves, pneumatic valves, pressure regulators, FRL and other pneunamic components

(4)控制系統

*縱切電機:臺灣城邦電機

*縱切控制:英威騰變頻器

*排刀控制:威科達交流伺服系統

(4) Control System

* Slitting motor: Taiwan ChengBang motor

* Longitudinal control: YinWeiTeng converter

* Arrange Blades Control: WeiKeDa AC servo system

(5).全自動直刀橫切

*合金鋼直刀橫切,合金鋼精密研磨齒輪傳動,切紙平穩、整齊

*交流伺服電機、交流伺服控制器控制橫切,雙刀軸旋轉,橫切精度高、效率高

*橫切系統:威科達交流伺服系統

*橫切機出紙輸送採用上下皮帶夾緊及高摩擦力輸送帶,防止紙板翹曲、捲曲。

*變頻器控制橫切出紙輸送,輸送速度與紙板速度比例同步

(5). Automatic straight knife transverse cut

* Alloy straight knife transverse cut, alloy steel precision grinding gears, smooth cutter, tidy

* AC servo motors, AC servo controller control transverse cut, double rotary shafts, high cut-precision, high efficiency

* Transverse cut -system: WeiKeDa AC servo system

* Cut Unit output, select upper belt and lower belt feed output paper cardboard, high friction conveyor belt clamp, prevent cardboard warping, curl.

* Inverter control output after transverse cut, convey speed keep synchronous speed proportional with cardboard

(6).全自動堆碼

*堆紙架分四段輸送,橫向出紙採用伺服堆碼系統,伺服控制堆積床昇降

*空地台板輸入時可以平放兩塊,空地台板輸入床的長度2500mm,電動輸入

*載有成品紙板的地台板輸出床的長度7500mm

(6). Automatic stacking

* Stacker conveyor frame is divided into four horizontal convey sections, stacking the paper sheets using servo system, servo control stack bed lift

* Empty pallets can in-feed two pieces of pallets, length of the input bed 2500mm, electro-motion input.

* Finished cardboard pallets output conveyor frame length 7500mm

(7).全自動控制

*標配10〞彩色觸摸屏,方便操作監視和訂單管理

*紙板輸送、橫切、堆碼全自動控制,可不停機換單,提高生產效率、提高紙板質量、減少換單浪費、減少操作工、降低操作工勞動強度

*獨立密封控制櫃,電器設備在無塵、乾燥環境下運行,提高可靠性、減少故障

(7). Automatic control

* Standard 10 "color touch screen, easy operate and monitor, and orders management

* Cardboard Automatic control of transport, transverse cutting, stacking, without stopping changing order, increase productivity, improve quality of the board, reduce waste while changing order, reducing the operators, reducing operator labor intensity.

* Independent sealed control cabinets, electrical equipment under clean, dry operating environment, improve reliability and reduce failure